ADVANCED ROBOTICS FOR OPTIMIZING ASSET MANAGEMENT

Operating a power system means facing many challenges: aging assets, growing demand and the proliferation of operating constraints. As the owner-operator of a very extensive grid, Hydro-Québec has developed maintenance strategies and innovative robotic tools to keep facilities running smoothly and extend their useful life.

Preventive robotics

Hydro-Québec has solid expertise in using robotics to inspect and maintain power generation, transmission and distribution infrastructure: overhead and underground lines, transformer substations, hydraulic turbines, underwater civil engineering structures, etc. Designed to ensure the reliability and long-term operability of facilities and equipment, our technologies meet the most stringent asset management standards.

Innovations based on 20 years of specialized robotics research

Researchers, engineers and technicians at Hydro-Québec’s research institute, IREQ, have been pooling their expertise in mechanics, IT and electronics to develop solutions for more than 20 years.

LineRanger

LineRanger is an innovation solution for inspecting power transmission lines.

Linedrone

LineDrone is a drone prototype specialized in direct-contact inspection of high-voltage transmission lines.

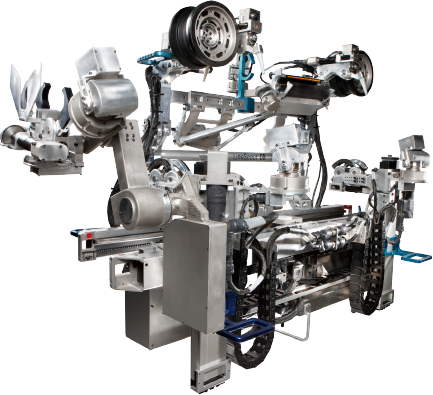

LineScout

LineScout is a robotic platform designed to inspect energized transmission lines and carry out minor repairs.

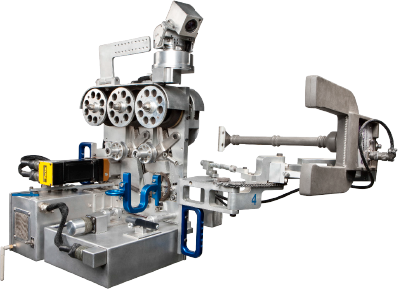

LineROVer

LineROVer is a remotely-operated robot designed to inspect energized transmission and distribution lines and carry out minor repairs.

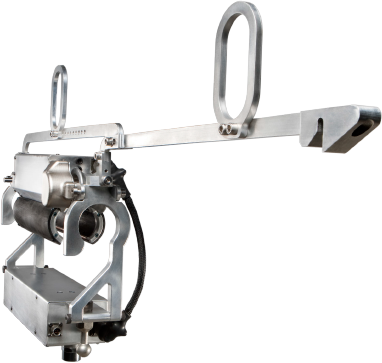

LineCore

LineCore is a corrosion detector that provides detailed information about the condition of the galvanic protection on transmission and distribution line conductors.

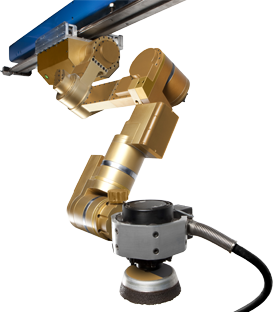

Scompi

The Scompi system offers an alternative to replacing and factory-refurbishing turbines. It is also able to perform in situ repairs of guide rails and spherical valves.

WireScan

Our 3D inspector of vertical surfaces, the WireScan robot measures the geometry of surfaces and long vertical sections above and below the waterline.

Predict

Infrastructure refurbishment, equipment replacement, maintenance project prioritization and investment decisions must be based on accurate strategic information.

As the owner of a power grid and generating facilities, we face many challenges: aging assets, growing demand and proliferating operating constraints. To help maintain our facilities to the highest standards, Hydro-Québec has developed a range of technological solutions to guide the best asset management decisions.

Prevent

Anticipating the evolving condition of our equipment lets us take action at the optimal time. For this, we need reliable data.

The prevention solutions developed by Hydro-Québec provide unparalleled data quality. Whether we’re diagnosing the condition of a transmission line conductor, visualizing the condition of a head gate slot or modeling the damaged profile of a turbine runner, our technologies give us access to the best prevention data on the market.

Correct

Some interventions cannot wait—and at the same time, must have little to no impact on energy delivery.

Hydro-Québec’s solutions make it possible to perform in situ interventions with previously unimaginable efficiency and safety while maximizing equipment availability.